Flow Controls Positive Displacement Flow Meter FCM-Series meters are the most accurate and reliable meters for the purpose of custody transfer of fuels (refined and alternative). With the advantage of simple design language and durable construction, together with consistently time-proven record accuracy, is why clients choose Flow Controls for the purpose of fluid custody transfer

No metal to metal connection which means that the measuring chamber suffers little to none deterioration

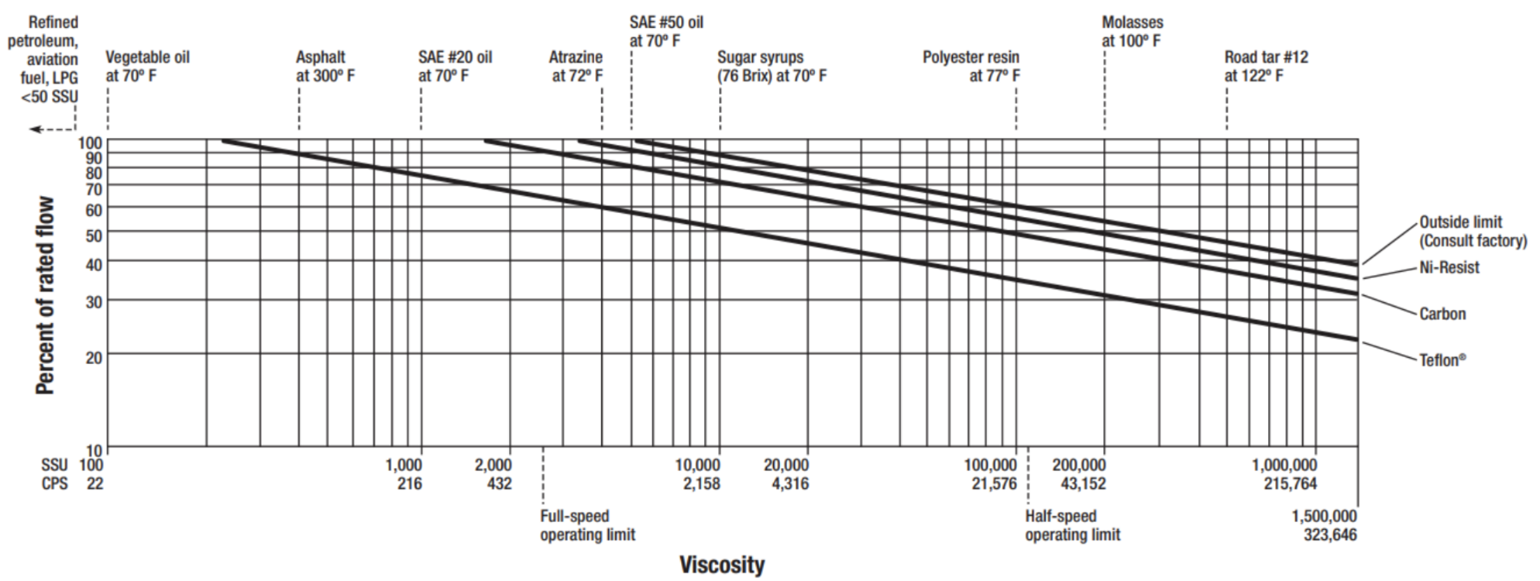

Meters can accurately calculate liquid products from less than 30 SSU up to 1500000 SSU

Equipped with easily modifiable NPT Connection, FCM Series provides unrivalled adaptability to suit your needs

Meters conformed to PEI and CE accuracy requirements

Products can be calculated correctly from -40 °C Up to 71 °C

High Pressure Rating – Up to 10.5 Bar Max Pressure Rating

Repeatability: Achieves 0.02% or better accuracy across the entire flow range.

FCM-40® Meters are designed for accurately measuring refined petroleum products, including leaded and unleaded gasoline, aviation fuels, fuel oils, diesel fuel, kerosene, and ethylene glycol (antifreeze), all at their rated capacity.

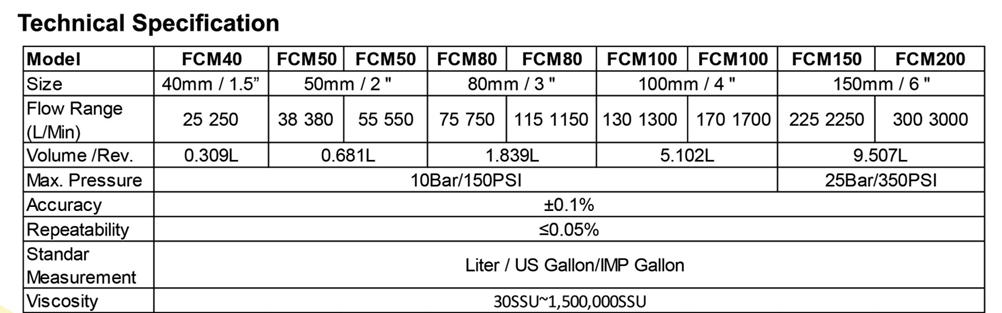

FCM-40 Series Spec

FCM-50® Meters are designed for accurately measuring refined petroleum products, including leaded and unleaded gasoline, aviation fuels, fuel oils, diesel fuel, kerosene, and ethylene glycol (antifreeze), all at their rated capacity.

FCM-50 Series Spec

FCM-80® Meters are designed for accurately measuring refined petroleum products, including leaded and unleaded gasoline, aviation fuels, fuel oils, diesel fuel, kerosene, and ethylene glycol (antifreeze), all at their rated capacity.

FCM-80 Series Spec

FCM-100® Meters are designed for accurately measuring refined petroleum products, including leaded and unleaded gasoline, aviation fuels, fuel oils, diesel fuel, kerosene, and ethylene glycol (antifreeze), all at their rated capacity.

FCM-100 Series Spec

FCM-150® Meters are designed for accurately measuring refined petroleum products, including leaded and unleaded gasoline, aviation fuels, fuel oils, diesel fuel, kerosene, and ethylene glycol (antifreeze), all at their rated capacity.

FCM-150 Series Spec

Use the chart below to determine the maximum meter flow rate based on meter bearing material and product viscosity:

If the point is above the slope, the pressure loss exceeds allowable limits. Consider using a larger meter, reducing the flow rate, or selecting different bearing materials.

Every industry has unique needs, and we understand that one-size-fits-all solutions simply won’t do.