Why It’s the Gold Standard for High-Accuracy Liquid Measurement

Introduction: When Every Drop Counts

Imagine you’re fueling a fleet, batching high-viscosity chemicals, or billing based on fuel volume. Would you trust your operation to vague estimates? Or do you want pinpoint accuracy, backed by engineering you can trust?

That’s where the Positive Displacement Flow Meter comes in.

Unlike other technologies that estimate flow based on velocity or pressure differentials, a positive displacement (PD) meter physically captures and measures the exact amount of fluid passing through it.

And at Flow Controls Metering LLC, based in California, we engineer PD meters that deliver performance you can count on—day in and day out, gallon after gallon.

What is a Positive Displacement Flow Meter?

A Positive Displacement Flow Meter (PD meter) is a volumetric flow device that directly measures the fluid volume by trapping fixed amounts of fluid and counting the number of times the chamber fills and empties.

This type of meter operates almost like a fuel pump—it measures what actually passes through, making it ideal for high-accuracy applications such as:

- Fuel dispensing

- Custody transfer

- Oil distribution

- Chemical batching

- Viscous or non-conductive fluids

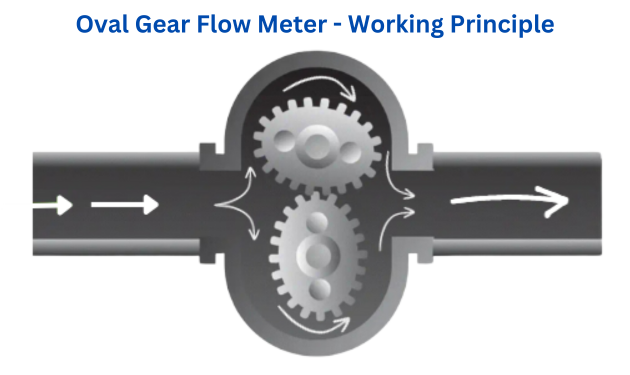

How Does a Positive Displacement Flow Meter Work?

At its core, a PD meter divides the fluid into precise volumes using mechanical components such as:

- Oval gears

- Rotary pistons

- Sliding vanes

- Helical rotors

- Nutating disks

As the fluid moves through the meter, it drives these components, and the number of revolutions or cycles is directly related to the volume. These movements are then converted into readable digital or analog outputs.

Key Characteristics:

- Measures actual volume, not inferred velocity

- Works without flow conditioning

- No need for conductive fluids or power (in mechanical models)

Types of Positive Displacement Flow Meters

1. Oval Gear PD Meters

Two oval gears rotate as liquid flows through, each gear’s rotation representing a known volume.

Best For:

Lubricants, fuels, chemicals

Advantages:

Compact, high viscosity tolerance

2. Rotary Vane PD Meters

Vanes mounted on a rotor sweep fluid in segmented chambers.

Best For:

Petroleum products, light oils

Advantages:

Smooth flow, compact footprint

3. Sliding Piston PD Meters

A piston moves within a chamber, displacing fluid with each cycle.

Best For:

Diesel, kerosene, heating oil

Advantages:

Great for small volumes with high accuracy

4. Nutating Disk PD Meters

A disk wobbles (“nutates”) inside a spherical chamber, pushing fluid out in controlled volumes.

Best For:

Water and oil service

Advantages:

Low cost, moderate precision

Why Choose a Positive Displacement Flow Meter?

| Benefit | Why It Matters |

|---|---|

| 💯 High Accuracy | Delivers up to ±0.2% even on viscous or pulsating flow |

| 🧪 No Fluid Conductivity Needed | Ideal for oils, fuels, and non-water-based liquids |

| 🛠️ Simple Maintenance | Minimal moving parts = longer lifespan |

| ⚙️ No Straight Pipe Runs | Installs in tight spaces; no need for upstream/downstream piping |

| 💵 Billing and Custody Ready | Ideal for metering in commercial exchanges or regulated environments |

Applications of PD Flow Meters

🚛 Fuel Trucks & Terminals

Positive displacement meters are widely used in diesel fuel delivery, aviation fueling, and biodiesel metering. Their high accuracy makes them essential for invoicing and bulk fuel tracking.

🏭 Chemical Processing

In batch chemical operations, PD meters handle corrosive, viscous, or mixed fluids while maintaining precise volume control.

🧴 Lubricant Dispensing

From engine oils to hydraulic fluids, positive displacement meters excel in handling thick, non-conductive fluids where electromagnetic or turbine meters fail.

🧪 Laboratory and Pharmaceutical Applications

Smaller PD meters (especially piston types) are used in dosing, sampling, and micro-batching.

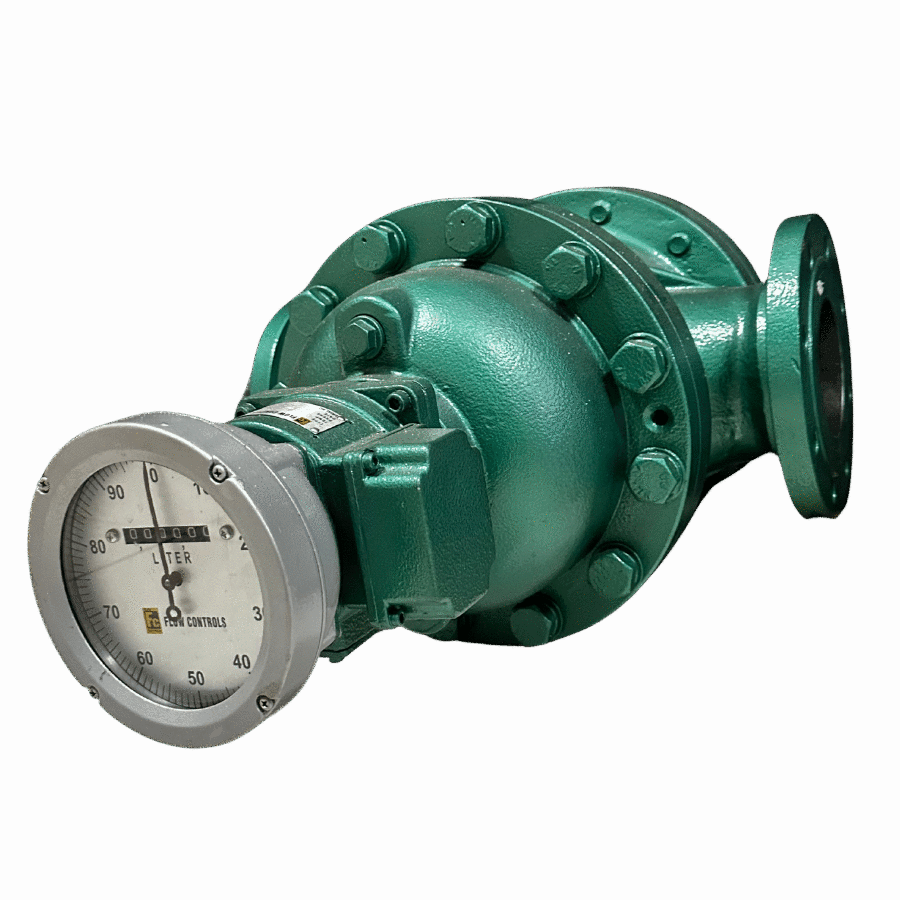

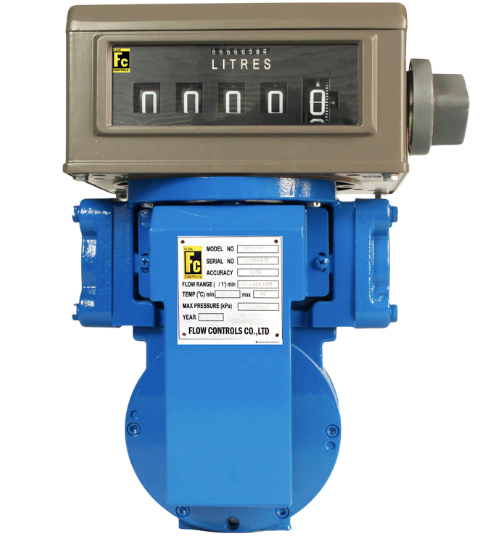

Flow Controls PD Meters: Built for Performance

At Flow Controls Metering LLC, we specialize in industrial-grade FCM Series Positive Displacement Meters—trusted in fuel depots, fleet fueling stations, and industrial plants across the U.S. and beyond.

🔧 FCM80 Positive Displacement Meter

- Flow Range: 20–800 L/min

- Accuracy: ±0.2%

- Temperature Range: -20°C to +80°C

- Output: Pulse, RS485, 4–20mA

- Build: Aluminum body, stainless-steel internals

- Mounting: Horizontal/vertical, flange or NPT

Common Uses: Diesel trucks, marine fueling, bulk tank monitoring

🌍 Global Partnership: ferindo.id

In Southeast Asia, Flow Controls products are distributed and supported through Ferindo Energi Instrumen, offering real-time support, on-site calibration, and custom installations.

Case Study: PD Meters in Action

Client: Fuel Distribution Hub, Houston, TX

Challenge: Frequent miscounts with turbine meters due to thick diesel blends and aeration.

Solution: Installed Flow Controls FCM80 PD Meters with RS485 output and digital displays.

Results:

- Reduced billing disputes by 90%

- Improved fuel reconciliation accuracy by 0.6%

- Integrated seamlessly into SCADA dashboard

Positive Displacement Meters vs. Other Flow Technologies

| Feature | PD Meters | Turbine Meters | Electromagnetic Meters |

|---|---|---|---|

| Accuracy (liquids) | ±0.2% | ±0.5%–1% | ±0.5%–1% |

| Conductivity Required | No | No | Yes |

| Ideal for Viscous Fluids | Yes | No | Sometimes |

| Moving Parts | Yes | Yes | No |

| Calibration Stability | Excellent | Moderate | High |

Smart Technology Integration

Flow Controls meters are smart meter–ready, with:

- Pulse outputs for counters

- 4–20mA analog for PLCs

- RS485/Modbus for real-time dashboards

- Optional local LCD totalizer with user interface

Whether you’re tracking volume, flow rate, or diagnostics, our PD meters connect with the tools you already use.

Maintenance & Calibration

Though PD meters are robust, proper maintenance extends life and accuracy:

Tips:

- Calibrate at least once annually (more for custody applications)

- Inspect seals and gears for wear

- Use inline strainers to prevent particulates

- Keep records of calibration and performance

Flow Controls offers field calibration kits and support services through our dealer network and ferindo.id.

Customer Reviews

“The FCM series meters from Flow Controls are the most reliable I’ve used in 20 years of fuel management. They just work—day in, day out.”

– Michael B., Terminal Operator, California

“PD meters from Flow Controls helped us solve flow discrepancies with high-viscosity lube oils. No more guesswork.”

– Nina L., Chemical Engineer

Frequently Asked Questions

Q: Can a PD meter handle diesel, biodiesel, or ethanol blends?

A: Absolutely. Our FCM meters are compatible with most petroleum-based products, including biodiesel up to B100.

Q: Are Flow Controls meters certified for custody transfer?

A: Yes. Our PD meters comply with API, OIML, and ISO measurement standards.

Q: Do PD meters require power?

A: Basic mechanical models do not. Smart versions with digital outputs do require minimal power for electronics.

Final Thoughts: Precision You Can Trust

In environments where accuracy equals profitability, Positive Displacement Flow Meters stand above the rest. Whether you’re moving diesel, lube oil, or chemicals, these meters offer unmatched reliability, even in challenging conditions.

And when you choose Flow Controls Metering LLC, you’re choosing:

- U.S.-based support

- ISO-calibrated precision

- Modular, easy-to-install designs

- A legacy of trust in flow solutions

📞 Ready to Measure with Confidence?

Get in touch with our experts to find the right PD meter for your needs:

🔗 www.fcmeter.com

🌐 Southeast Asia Partner: ferindo.id

Flow Controls Metering LLC – Flow with Confidence. Measure with Precision.

Sources & Further Reading

Engineering Toolbox – Fluid Measurement

API – Manual of Petroleum Measurement Standards